Knife Grinds: A Complete Guide to Choosing the Right Blade Grind

When choosing a knife, the right blade grind can make all the difference. A knife’s grind is ultimately what supports the edge itself, and the type of grind can drastically affect the way it cuts. Although there is no single “best” blade grind, each one has its own set of strengths and weaknesses that make it better at certain cutting tasks, so read on to find the best blade grind for you:

How does a knife work?

A knife is technically a wedge, which works by changing the direction of a force to push material apart. Downward force at the thick end of the wedge is transferred into sideways force along the sloping sides of the wedge, which separates material as it passes through. The thinner the wedge, the easier it passes through material; the thicker the wedge, the stronger it is.

A good knife must balance cutting efficiency and strength—too thin, and the blade becomes too delicate; too thick, and the blade requires too much force to cut. The type of blade grind affects the balance of these properties by changing the geometry of the wedge, which ultimately determines how the knife moves through material.

Flat Grind:

Flat grinds feature straight bevels on either side of the blade that taper towards the cutting edge. There are two main kinds of flat grinds, full-flat and saber.

Full Flat Grind:

Full flat grinds, as seen on this Spyderco Military 2, taper across the entire width of the blade from the spine to the edge. This makes them great at slicing tasks, because the gradual approach to the edge helps separate material in a smooth, uninterrupted fashion. For this reason, many kitchen and butcher knives feature a full flat grind.

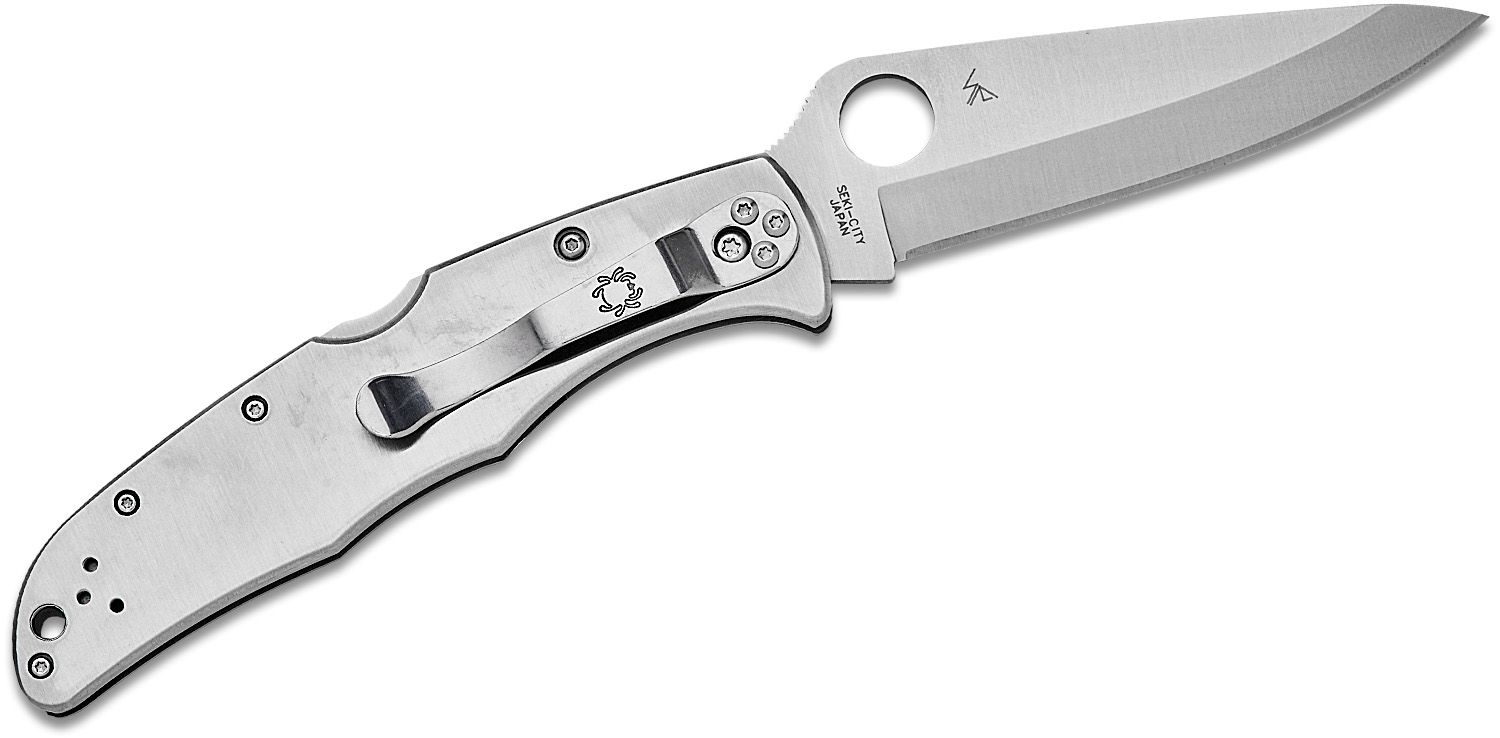

Flat Saber Grind:

Flat Saber grinds, as seen on this Spyderco Endura, don’t start tapering towards the edge until roughly halfway down the blade. This makes them much stronger than full flat grinds at the expense of slicing efficiency. Flat saber grinds are a great choice when you expect to be doing rougher work, or if you demand strength and reliability on such as a survival knife.

Hollow Grind:

Hollow grinds have a concave, inwardly curved surface on each side of the blade.

Generally, hollow grinds maintain their thinness behind the edge further up the blade than other grinds, making them superlative slicers that excel in precision cutting. As with flat grinds, you can increase the strength of a hollow grind by making the geometry more obtuse by bringing the grind panel closer to the edge. Even so, they are not the go-to choice for strenuous tasks like chopping due to potential durability concerns.

One unique advantage of hollow grinds, however, is their ability to be re-sharpened multiple times without the edge getting any thicker. In addition to traditional straight razors, hollow grinds are often found on hunting and everyday carry knives, where their unparalleled slicing power pays dividends.

Convex Grind:

Convex grinds have an outwardly curved surface on each side of the blade, making them the opposite of hollow grinds.

Likewise, their properties are also opposite, as they boast strength and stability over pure slicing power. Convex-ground blades tend to be more expensive than comparable knives with different grinds, because they require more hand work to create the proper geometry. Often, the main grind extends all the way to edge without a secondary edge bevel, making them excellent at wood-working and other carving tasks while also making them more challenging to sharpen. Because they are durable and well-suited for heavy cutting tasks, they are prized by survivalists, bushcrafters, and outdoors enthusiasts of all kinds.

Scandi Grind:

A Scandi grind has a single bevel on either side of the blade that extends all the way to the apex, with no secondary edge bevel.

These knives are simple, easy to sharpen, and excellent for woodworking and carving.

Chisel Grind:

Chisel grinds are asymmetrical, having a bevel on only one side similar to a chisel.

This specialized grind works great in certain applications, such as kitchen knives designed specifically for right-handed chefs, or self-defense knives meant to be carried flush against the body, for example. However, its asymmetry limits its suitability for general applications, as they tend to “lean” one way while cutting.

Compound Grind:

A compound grind embraces versatility by combining different grind types on the same blade.

Sometimes, as on these Boker Tracker knives, each grind is meant to do different tasks, making a knife more multi-purpose. Sometimes, they are meant to balance the attributes of various grinds to optimize its overall performance. And sometimes, especially on custom knives, they are simply meant to showcase the skill of the knifemaker!

The selection of the appropriate blade grind plays a pivotal role in determining the performance of a knife. The grind, serving as the foundation for the blade’s edge, significantly influences its cutting capabilities. While there is no universally superior blade grind, each type comes with distinct strengths and weaknesses tailored to specific cutting tasks. We hope this page has helped you discover the optimal blade grind for your needs.